Industrial CT inspection system for additive manufacturing has achieved a major breakthrough

2024-12-18 00:00

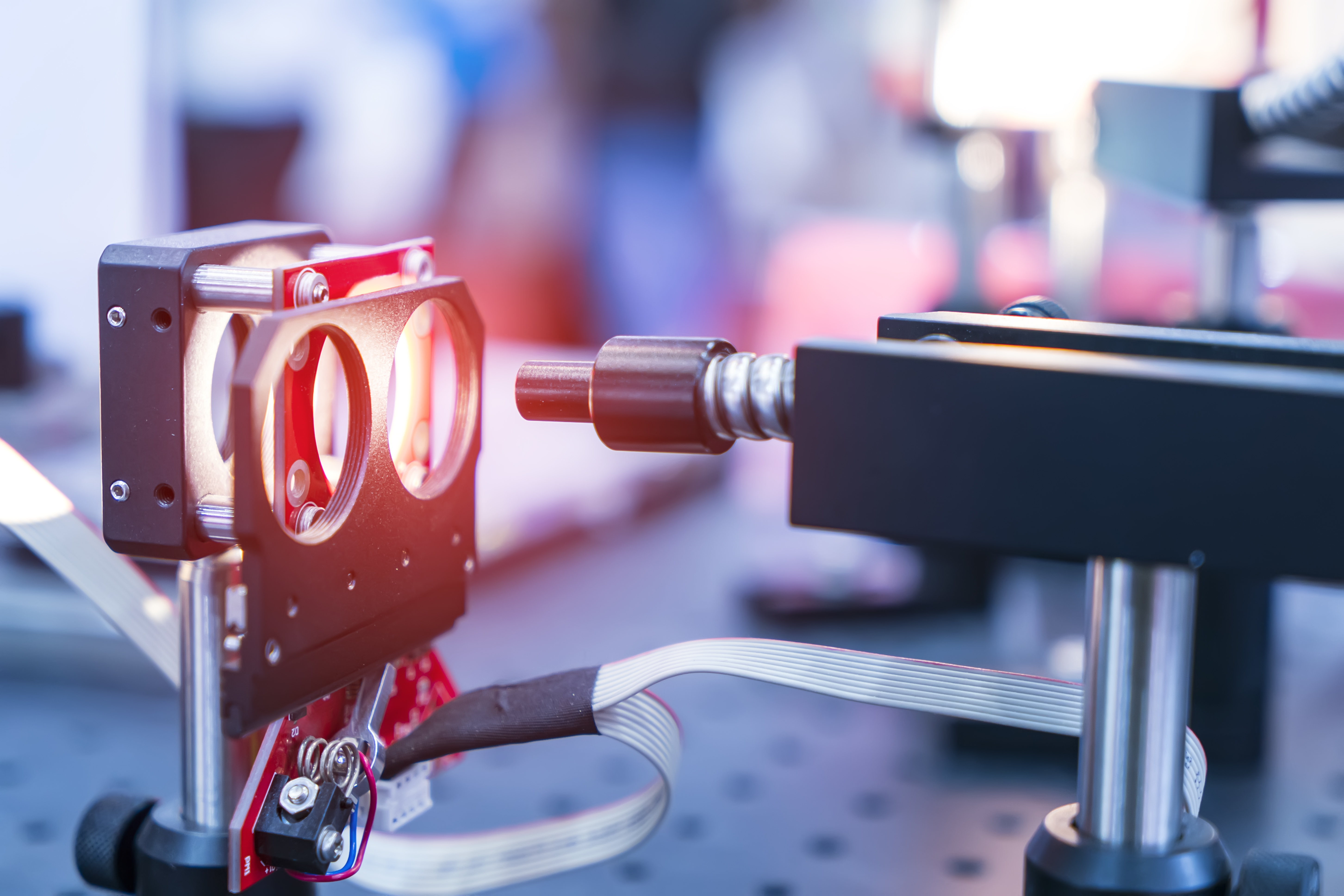

A significant breakthrough has occurred in the field of additive manufacturing with the introduction of a cutting-edge Industrial CT inspection system for additive manufacuring.

This innovative system is specifically designed to meet the unique challenges and requirements of additive manufacturing processes. It offers a comprehensive and accurate way to inspect 3D-printed parts, ensuring their quality and integrity.

The Industrial CT inspection system for additive manufacuring provides detailed internal and external analysis of the printed components, detecting any potential defects or irregularities that might otherwise go unnoticed. This level of precision is crucial for industries relying on additive manufacturing for critical applications.

With its ability to quickly and efficiently assess a large number of parts, it streamlines the production process and helps manufacturers save time and resources. It also enables them to make informed decisions regarding process optimization and quality control.

The arrival of this advanced inspection system is set to enhance the reliability and performance of additive manufactured products across various sectors. It is opening up new possibilities in industries such as aerospace, automotive, and medical, where precision and quality are of utmost importance.

As additive manufacturing continues to grow and evolve, the Industrial CT inspection system for additive manufacuring is playing a vital role in ensuring its success and driving innovation in this exciting field.