Revolutionizing Defense and Shipbuilding Industries with Industrial CT Inspection System

2025-04-03 00:00

March 2025 – In a significant advancement for the defense and shipbuilding sectors, the latest Industrial CT Inspection System is setting new standards for quality control and structural integrity analysis. As the demand for precision and reliability in military and naval applications grows, this cutting-edge technology is poised to enhance manufacturing processes, ensuring the highest levels of safety and performance for critical defense and maritime assets.

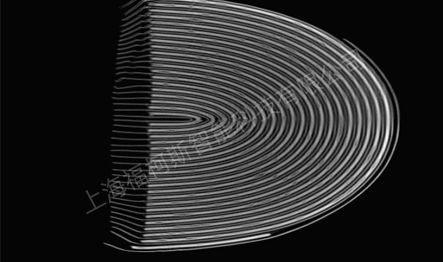

The Industrial CT Inspection System uses advanced X-ray technology to generate high-resolution 3D images of complex components, enabling manufacturers to detect defects, measure material thickness, and assess internal structures without disassembling or damaging the parts. This non-destructive testing (NDT) solution is particularly valuable in industries where the integrity of materials is paramount, such as the production of defense equipment and naval vessels.

Key Benefits for Defense and Shipbuilding:

1. Enhanced Quality Control: The system allows for the detailed inspection of military components, including weaponry, armored vehicles, and aircraft parts, ensuring they meet the strictest performance and safety standards.

2. Precision in Shipbuilding: For shipbuilding manufacturers, the Industrial CT Inspection System offers a reliable method for detecting structural flaws, cracks, or corrosion in ship hulls and vital components, ensuring ships are built to withstand extreme conditions.

3. Non-Destructive Testing: This innovative system enables the inspection of materials and components without altering or damaging them, ensuring that critical defense and maritime assets remain intact throughout the evaluation process.

4. Improved Efficiency: By providing fast and accurate inspections, the Industrial CT Inspection System reduces the need for time-consuming manual inspections and rework, boosting overall productivity and reducing the risk of costly delays.

5. Cost-Effective: Although initially a significant investment, the long-term benefits of improved accuracy, reduced errors, and enhanced safety make the Industrial CT Inspection System a cost-effective solution for both defense contractors and shipbuilding companies.

A New Era for Defense and Shipbuilding Manufacturing

As nations invest in next-generation defense technologies and advanced naval capabilities, the need for reliable, high-quality production methods is more critical than ever. The Industrial CT Inspection System ensures that every component—whether part of a tank, naval vessel, or fighter jet—is thoroughly inspected, reinforcing the reliability and safety of the final product.

In addition to enhancing quality control, this technology also aligns with increasing global demands for stringent safety standards and sustainable manufacturing practices. By providing manufacturers with the tools to detect hidden flaws and ensure optimal performance, the Industrial CT Inspection System contributes to creating more robust and dependable defense and maritime systems.

Looking Ahead

With its transformative capabilities, the Industrial CT Inspection System is quickly becoming a must-have technology for industries where precision, safety, and efficiency are non-negotiable. The future of defense manufacturing and shipbuilding relies on this powerful tool to drive quality, reduce risks, and deliver superior products to protect both people and nations on land and at sea.

For more information on how the Industrial CT Inspection System can enhance your manufacturing processes, contact us today!