Industrial CT——Assisting additive manufacturing process innovation and quality improvement

2023-10-14 16:54

At present, additive manufacturing technology (3D printing technology) has become an indispensable application means in modern manufacturing. With advanced technology, it can realize the rapid manufacturing and production of complex parts and customized components.

In order to better observe the performance and changes of additively manufactured parts in real time, especially when the workpiece is subjected to specific external conditions such as heating or load, the Focus industrial CT system can provide high-resolution 3D imaging with non-destructive testing technology to accurately identify and quantify defects in parts.

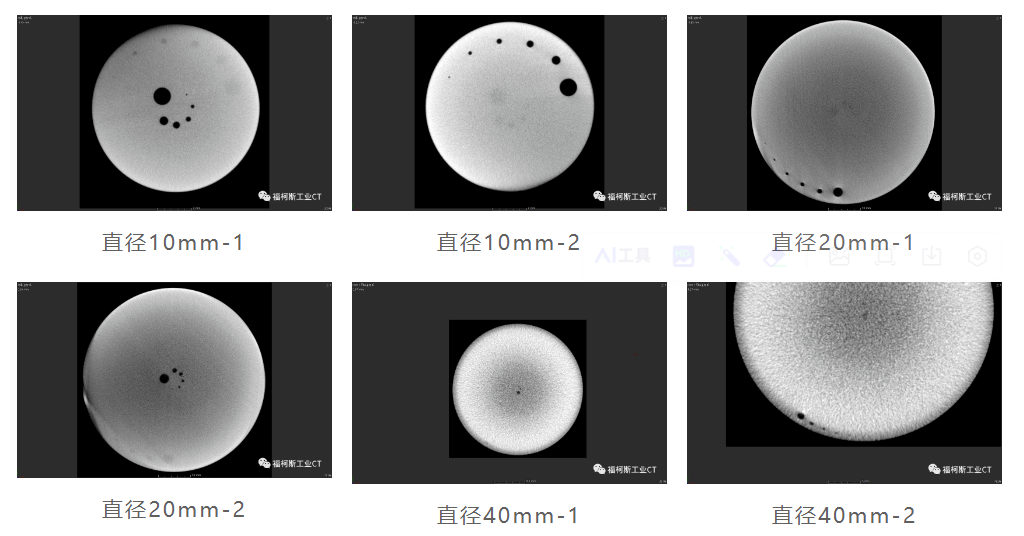

01 Detection accuracy

By performing CT scanning on standard parts, the accuracy of Shanghai Focus's equipment was verified, and the measured dimensions were still consistent with the standard parts.

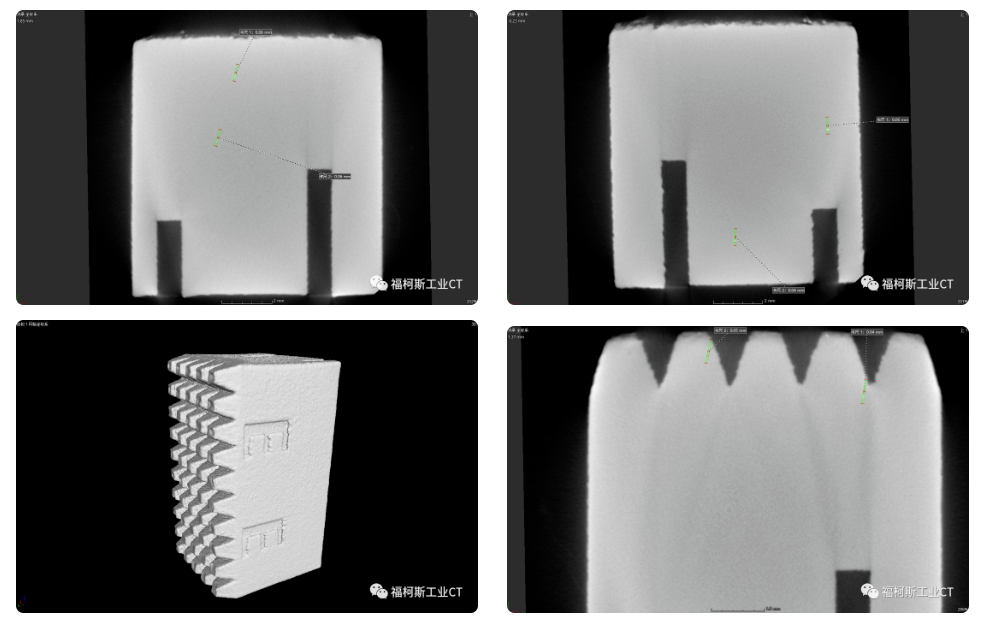

02 Internal and external geometric structure analysis

By scanning the additively manufactured workpiece through industrial CT, the internal and external geometric features can be fitted, and then the software independently developed by Shanghai Focus can use these to measure and create some feature size measurements and form and position tolerance evaluations that are different from this part.

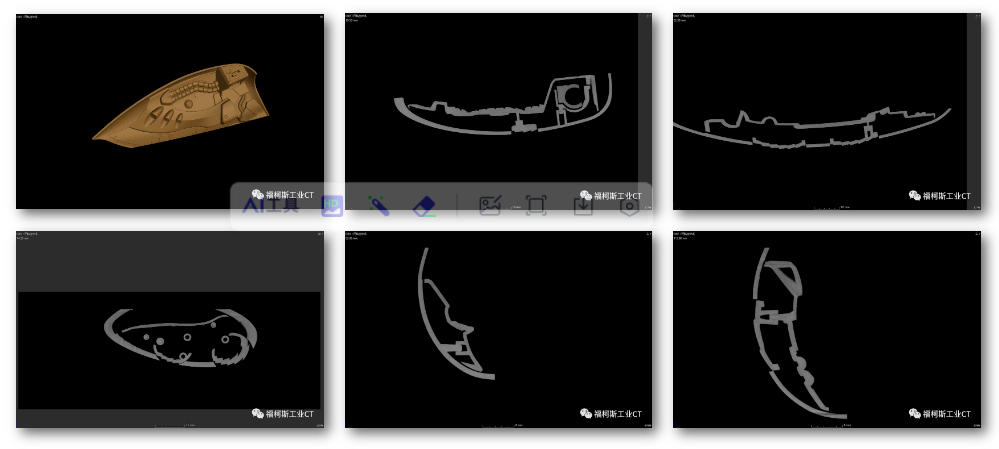

03 Internal Structure

Through CT holographic imaging scanning, the internal information of the workpiece can be obtained, helping customers to have a more comprehensive understanding of the defects of the workpiece and adjust the design and production process in time to achieve the expected quality goals.

About Focus

Shanghai Focus Intelligent Technology Co., Ltd. is a professional provider focusing on the R&D, production, sales and service of industrial CT holographic imaging equipment. It has currently achieved domestic substitution of software such as data acquisition and processing with completely independent intellectual property rights, image reconstruction in multiple modes, AI intelligent analysis, and data analysis. The company can provide both area array and line array detection services.

2025.09.30

2025.09.23