Revolutionizing Automotive Engineering with Industrial CT Scanning Services

2025-05-08 00:00

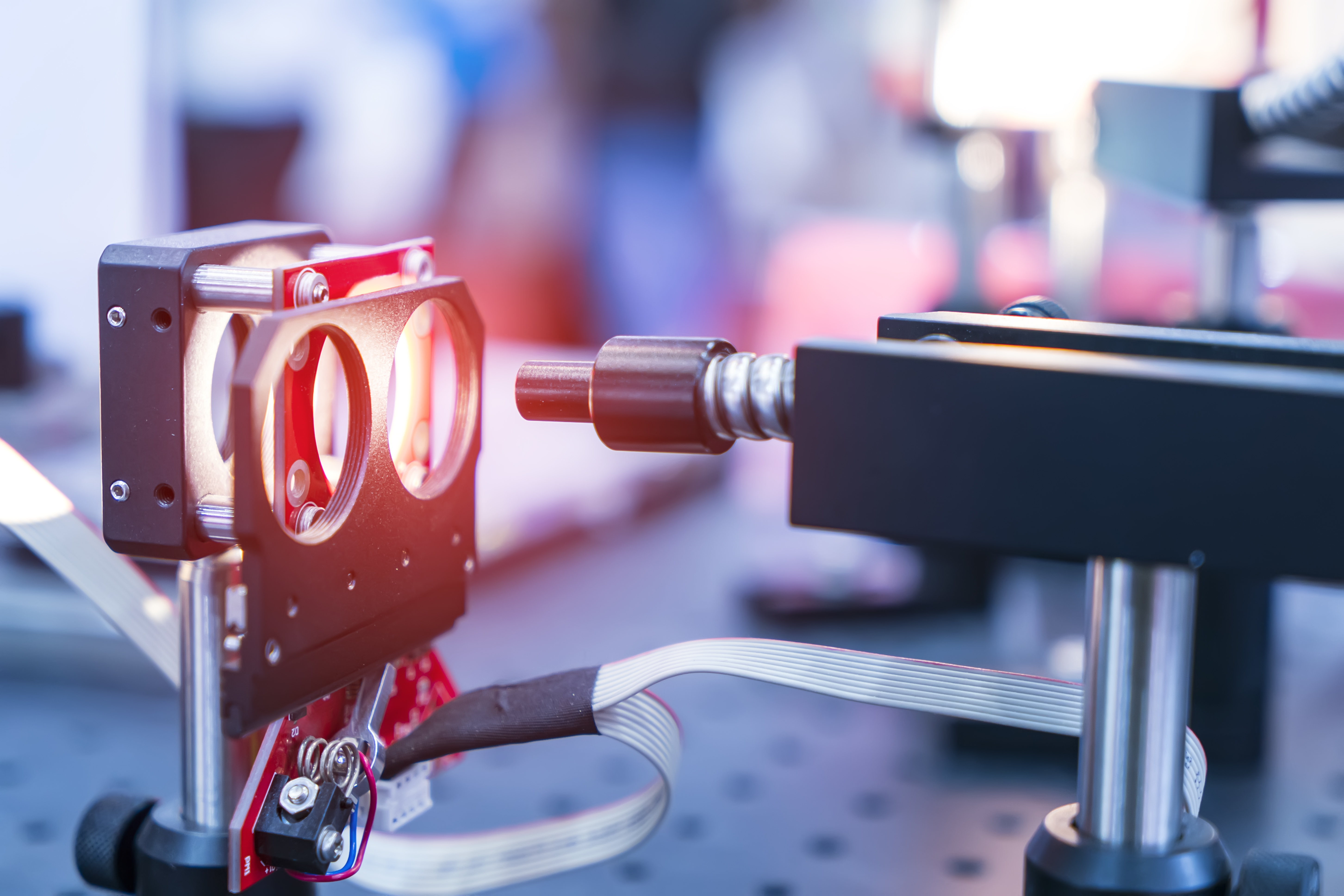

The automotive industry continues to evolve with cutting-edge technologies that streamline design, production, and quality assurance. One such innovation making waves in automotive engineering is the integration of Industrial Ct Scanning Services. This advanced technology is proving to be a game-changer, offering a non-destructive way to inspect automotive components at a microscopic level.

The Role of Industrial CT Scanning in Automotive Design:

Industrial CT scanning allows automotive engineers to analyze parts with unparalleled precision. By creating 3D digital models of components, this technology offers insights into the internal structures that traditional methods could miss. From engine parts to complex electronic assemblies, CT scanning ensures that every element meets stringent design specifications.

Accelerating the Prototyping Process:

One of the significant benefits of industrial CT scanning in the automotive sector is its ability to speed up the prototyping process. Engineers can quickly examine prototypes in their entirety, identifying issues such as air gaps, material inconsistencies, and structural weaknesses without having to dismantle or physically damage the parts. This not only reduces the time to market but also lowers production costs.

Enhancing Safety and Performance:

In an industry where safety and performance are paramount, CT scanning plays a crucial role in detecting hidden flaws in materials and assemblies. Whether it's inspecting critical safety components such as brake systems or monitoring the durability of lightweight materials used in electric vehicles, this technology ensures that only the highest-quality parts make it to the final product.

Quality Assurance and Manufacturing Optimization:

Industrial CT scanning supports the automotive manufacturing process by providing real-time feedback on part quality. This feedback loop helps manufacturers make adjustments early in production, minimizing defects and ensuring that parts conform to tight tolerances. Additionally, the ability to inspect complex geometries makes it ideal for the production of lightweight and high-performance parts, which are increasingly in demand in modern vehicles.

Applications in Electric and Autonomous Vehicles:

The rise of electric and autonomous vehicles brings about new challenges in parts design and material selection. Industrial CT scanning services allow for detailed analysis of battery cells, wiring systems, and electronic components, ensuring that these intricate systems function optimally. Furthermore, as the demand for lightweight structures grows, CT scanning enables the detailed inspection of advanced composites and alloys used in vehicle construction.

As automotive technology progresses towards smarter, safer, and more efficient vehicles, industrial CT scanning services will remain a critical tool in the engineering and manufacturing toolkit. By providing in-depth insights into component integrity, accelerating prototyping, and ensuring the highest levels of safety and performance, CT scanning is revolutionizing how the automotive industry designs and manufactures the vehicles of tomorrow.

2025.09.30

2025.09.23